Pipe Fittings Suppliers

Robust Special Metals is a trusted supplier of flanges for industries worldwide. We provide strong, reliable, and high-quality steel flanges that are used in piping systems across oil & gas, chemical plants, power stations, shipbuilding, and many more industries.

What are Pipe Fittings?

Common Applications of Buttweld Fittings

Flanges are often used with fittings and gaskets to make a tight joint. The fittings help guide or change the flow, and the flanges are the points that connect everything together. When used this way, the system stays strong but can still be taken apart when needed.

Common Applications of Pipe Flanges

Plumbing & Drainage

Plumbing systems need secure pipe joints to handle daily water use. Buttweld fittings prevent leaks and keep water moving without blockages. They support drainage lines in houses, buildings, and city systems. Their strength also makes them a good choice for underground use.

Oil & Gas Pipelines

Chemical & Petrochemical Plants

HVAC Systems

Food & Beverage Processing

Pharmaceutical Industry

Power Plants

Heating, cooling and ventilation systems run nonstop. Buttweld fittings keep pipe joints tight even when temperatures change quickly. They reduce air or water loss, which improves system efficiency. This helps cut energy waste and lowers repair needs.

Looking for trusted Pipe Fitting Suppliers in India?

Get high-quality Pipe Fitting at competitive prices – request a quote today!

Types of Pipe Fittings and and Their Uses in Piping Systems

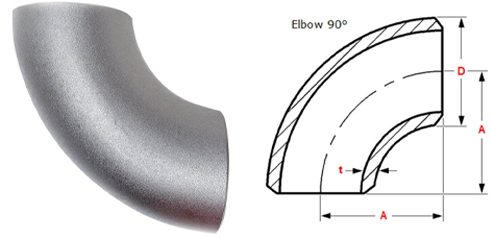

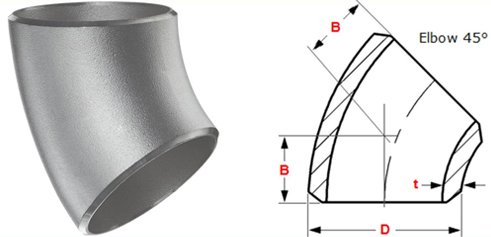

Elbow Fittings

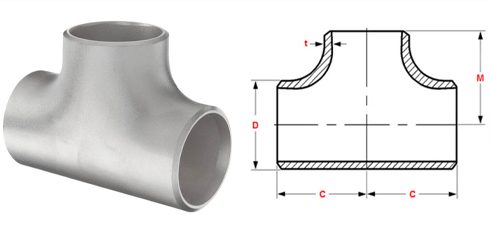

Tee Fittings

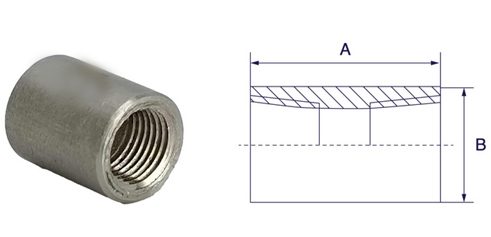

Coupler Fitting

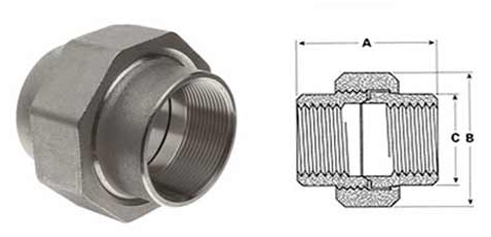

Union Fitting

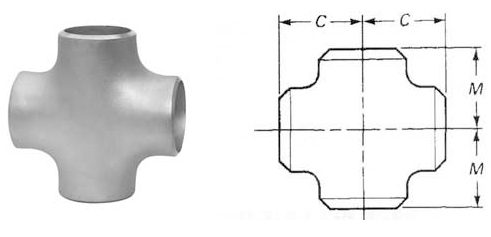

Cross Fittings

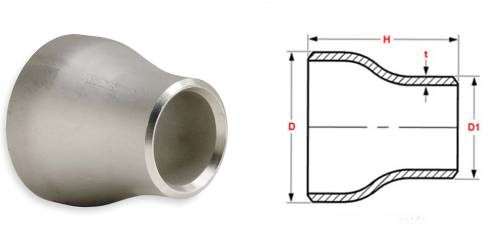

Reducer Fittings

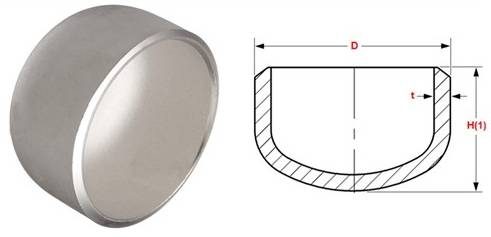

Cap Fittings

- Material Match: Pick a fitting made from the same material as the pipe. This avoids weak joints and improves durability.

- Size Accuracy: Check that the fitting size matches the pipe size exactly. Even small gaps can cause leaks or flow loss.

- Pressure Rating: Confirm that the fitting can withstand the system’s pressure. This prevents bursts and keeps the wires secure.

- Temperature Resistance: Select fittings that can withstand system heat or cold. This protects against cracks and failures.

- End Connection Type: Match the end type such as threaded, socket weld, or butt weld, to your piping design which ensures proper fit.

- Corrosion Resistance: Use corrosion-resistant fittings in systems carrying water, chemicals, or gas which extends service life.

- Standards Compliance: Choose fittings that meet ASME B16.11 or other standards. This guarantees safety and reliable performance.

- Ease of Maintenance: Pick fittings that allow quick inspection, cleaning or replacement. This reduces downtime and saves costs.

Pipe Fittings Specifications

| Buttweld Pipe Fittings | Specifications |

| Size | ½”NB to 48″NB in |

| Standard | Sch 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, STD, XS, XXS |

| Schedule | Sch 10s, 40s, 80s, 160s, XXS. |

| Specification | ASTM A182 / A403 & ASME SA182 / SA403 |

| Dimensions | ASME, ASTM , DIN, EN, JIS, AISI, BS, ANSI,. |

| Types | Elbow Pipe Fitting, Tee Pipe Fitting, Stub End Pipe Fitting, Reducer Pipe Fitting, Nipple Pipe Fitting, Bend Pipe Fitting, End Caps Pipe Fitting, Coupling Pipe Fitting |

Pipe Fittings Standards

Pipe fittings must meet particular standards to ensure safety, strength, and a proper fit. ASME B16.11 specifies material, size, pressure, and testing procedures. Following these standards helps to the long-term reliability of pipe systems in various sectors.

ASME B16.9

ASME B16.28

ASME B16.5

EN 10253

ISO 3419

JIS B2311

BS 1640

Pipe Fitting Materials

Stainless Steel Pipe Fittings

- Stainless Steel Pipe Fittings

- Stainless Steel 304 / 304L Pipe Fittings

- Stainless Steel 310 Pipe Fittings

- Stainless Steel 316 / 316L Pipe Fittings

- Stainless Steel 317 / 317L Pipe Fittings

- Stainless Steel 321 Pipe Fittings

- Stainless Steel 904L Pipe Fittings

- Stainless Steel 15-5 PH Pipe Fittings

- Stainless Steel 17-4 PH Pipe Fittings

Monel Pipe Fittings

Copper Nickel Pipe Fittings

Nickel Alloy Pipe Fittings

ASME B16.9 Dimension Chart

| Nominal Pipe Size | Outside Diameter | Center to Face | N | Back to Face | Center to Center | Length ‘L’ MS SS P43 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | mm | A | B | C | E | F | G | R | M | S | L | L | ||

| 1/2 | 15 | 21.3 | 38.00 | 16.0 | 25.0 | 25.0 | 48.0 | 25.0 | 48.0 | 76.0 | – | 35.0 | 50.8 | 76.2 |

| 3/4 | 20 | 26.7 | 29.00 | 11.0 | 29.0 | 25.0 | 43.0 | – | 43.0 | 57.0 | – | 43.0 | 50.8 | 76.2 |

| 1 | 25 | 33.4 | 38.00 | 22.0 | 38.0 | 25.0 | 38.0 | 56.0 | 41.0 | 76.0 | 51.0 | 51.0 | 50.8 | 101.6 |

| 1 1/4 | 32 | 42.2 | 48.00 | 25.0 | 48.0 | 32.0 | 38.0 | 70.0 | 52.0 | 95.0 | 64.0 | 64.0 | 50.8 | 101.6 |

| 1 1/2 | 40 | 48.3 | 57.15 | 29.0 | 57.0 | 38.0 | 38.0 | 83.0 | 62.0 | 114.0 | 76.0 | 73.0 | 50.8 | 101.6 |

| 2 | 50 | 60.3 | 76.00 | 35.0 | 64.0 | 51.0 | 38.0 | 106.0 | 81.0 | 152.0 | 102.0 | 93.0 | 63.5 | 152.4 |

| 2 1/2 | 65 | 73 | 95.25 | 44.0 | 76.0 | 64.0 | 38.0 | 132.0 | 100.0 | 191.0 | 127.0 | 105.0 | 63.5 | 152.4 |

| 3 | 80 | 88.9 | 114.30 | 51.0 | 86.0 | 76.0 | 51.0 | 159.0 | 121.0 | 229.0 | 152.0 | 127.0 | 63.5 | 152.4 |

| 3 1/2 | 90 | 101.6 | 133.35 | 57.0 | 95.0 | 89.0 | 64.0 | 184.0 | 140.0 | 267.0 | 178.0 | 140.0 | 76.2 | 152.4 |

| 4 | 100 | 114.3 | 152.0 | 63.0 | 105.0 | 102.0 | 64.0 | 210.0 | 159.0 | 305.0 | 203.0 | 157.0 | 76.2 | 152.4 |

| 5 | 125 | 141.3 | 190.0 | 79.0 | 123.0 | 127.0 | 76.0 | 262.0 | 197.0 | 381.0 | 254.0 | 186.0 | 76.2 | 203.2 |

| 6 | 150 | 168.3 | 229.0 | 95.0 | 143.0 | 152.0 | 89.0 | 313.0 | 237.0 | 457.0 | 305.0 | 216.0 | 88.9 | 203.2 |

| 8 | 200 | 219.1 | 305.0 | 127.0 | 178.0 | 203.0 | 102.0 | 414.0 | 313.0 | 610.0 | 406.0 | 270.0 | 101.6 | 203.2 |

| 10 | 250 | 273.1 | 381.0 | 159.0 | 216.0 | 254.0 | 127.0 | 515.0 | 391.0 | 762.0 | 508.0 | 324.0 | 127 | 254 |

| 12 | 300 | 323.9 | 457.0 | 190.0 | 254.0 | 303.0 | 152.0 | 619.0 | 467.0 | 914.0 | 610.0 | 381.0 | 152.4 | 254 |

| 14 | 350 | 355.6 | 533.0 | 222.0 | 279.0 | 356.0 | 165.0 | 711.0 | 533.0 | 1067.0 | 711.0 | 413.0 | 152.4 | 305.0 |

| 16 | 400 | 406.4 | 610.0 | 254.0 | 305.0 | 406.0 | 178.0 | 813.0 | 610.0 | 1219.0 | 813.0 | 470.0 | 152.4 | 305.0 |

| 18 | 450 | 457.2 | 686.0 | 286.0 | 343.0 | 457.0 | 203.0 | 914.0 | 686.0 | 1372.0 | 914.0 | 533.0 | 152.4 | 305.0 |

| 20 | 500 | 508 | 762.0 | 318.0 | 381.0 | 508.0 | 229.0 | 1016.0 | 762.0 | 1524.0 | 1016.0 | 584.0 | 152.4 | 305.0 |

| 22 | 550 | 559 | 838.0 | 343.0 | 419.0 | 559.0 | 254.0 | 1118.0 | 838.0 | 1676.0 | 1118.0 | 614.4 | 152.4 | 305.0 |

| 24 | 600 | 610 | 914.0 | 381.0 | 432.0 | 610.0 | 267.0 | 1219.0 | 914.0 | 1829.0 | 1219.0 | 692.0 | 152.4 | 305.0 |

| 26 | 650 | 660 | 991.0 | 406.0 | 495.0 | 660.0 | 267.0 | – | – | – | – | – | – | – |

| 28 | 700 | 711 | 1067.0 | 438.0 | 521.0 | 711.0 | 267.0 | – | – | – | – | – | – | – |

| 30 | 750 | 762 | 1143.0 | 470.0 | 589.0 | 762.0 | 267.0 | – | – | – | – | – | – | – |

| 32 | 800 | 813 | 1219.0 | 502.0 | 597.0 | 813.0 | 267.0 | – | – | – | – | – | – | – |

| 34 | 850 | 864 | 1295.0 | 533.0 | 635.0 | 864.0 | 267.0 | – | – | – | – | – | – | – |

| 36 | 900 | 914 | 1372.0 | 565.0 | 673.0 | 914.0 | 267.0 | – | – | – | – | – | – | – |

| 38 | 950 | 965.0 | 1448 | 600 | 711 | 965 | 305 | – | – | – | – | – | – | – |

| 40 | 1000 | 1016.0 | 1524 | 632 | 749 | 1016 | 305 | – | – | – | – | – | – | – |

| 42 | 1050 | 1067.0 | 1600 | 660 | 762 | 1067 | 305 | – | – | – | – | – | – | – |

| 44 | 1100 | 1118.0 | 1676 | 695 | 813 | 1118 | 343 | – | – | – | – | – | – | – |

| 46 | 1150 | 1168.0 | 1753 | 727 | 851 | 1168 | 343 | – | – | – | – | – | – | – |

| 48 | 1200 | 1219.0 | 1829 | 759 | 889 | 1219 | 343 | – | – | – | – | – | – | – |

Why Choose Robust Special Metals for Buttweld Fittings?

- Large Inventory with Ready Stock: We maintain a substantial stock of buttweld fittings in all standard sizes. This enables clients to receive speedy deliveries without waiting for production.

- Wide Material Selection: From stainless steel to alloy and duplex grades, we cover a broad range of materials. This ensures that you find fittings that meet both system requirements and industry standards.

- Competitive Prices for Bulk and Small orders: We provide reasonable pricing for both large and small purchases. Customers benefit from cost savings without compromising quality.

- International Quality Certifications: Our fittings meet ASME, ASTM and ISO specifications. Certified quality guarantees safe and dependable operation in key pipe systems.

- On-Time Delivery Worldwide: We ship orders on schedule to customers across the globe. Reliable logistics support makes sure your projects stay on track.

We Export Globally

Get high-quality Pipe Fittings suppliers in Mumbai. With custom solutions available.