Flanges Suppliers

What are Flanges in Piping?

Flanges and Fittings: How They Work Together

Flanges are often used with fittings and gaskets to make a tight joint. The fittings help guide or change the flow, and the flanges are the points that connect everything together. When used this way, the system stays strong but can still be taken apart when needed.

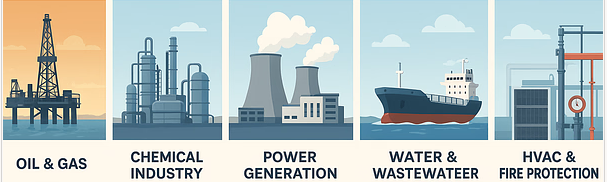

Common Applications of Pipe Flanges

Pipe flanges are used in high-pressure, high-temperature, and corrosive environments. They are found in oil and gas, refineries, shipbuilding, power plants, and construction industries, making them one of the most widely used piping accessories.

Oil & Gas

Flanges join pipeline sections, valves, fittings, and equipment in drilling, refining, and transportation. High-pressure and temperature-resistant types (like weld neck and blind flanges) are prevalent. Materials with strong corrosion resistance are often chosen for chemical exposure.

Chemical Industry

Used for aggressive chemical processing lines requiring frequent assembly/disassembly. Stainless steel and alloy flanges are common due to resistance to corrosive chemicals.

Power Generation

Essential for connecting pipelines, pumps, and turbines. Flanges tolerate high temperatures and pressures and are frequent in steam and cooling water systems.

Water & Wastewater Treatment

Connects pumps, valves, and pipes for water distribution and processing, allowing for easy maintenance and replacement.

Marine & Shipbuilding

Used in shipbuilding for piping, including cooling systems, fuel lines, and ballast systems. They are chosen for durability amid vibration, movement, and corrosion from seawater.

HVAC & Fire Protection

Flanges provide robust connections for large structural piping systems in commercial buildings, which is critical in fire sprinkler, HVAC, and plumbing systems.

Looking for trusted Flanges Suppliers in India?

Get high-quality flanges at competitive prices – request a quote today!

Types of Flanges and Their Uses in Piping Systems

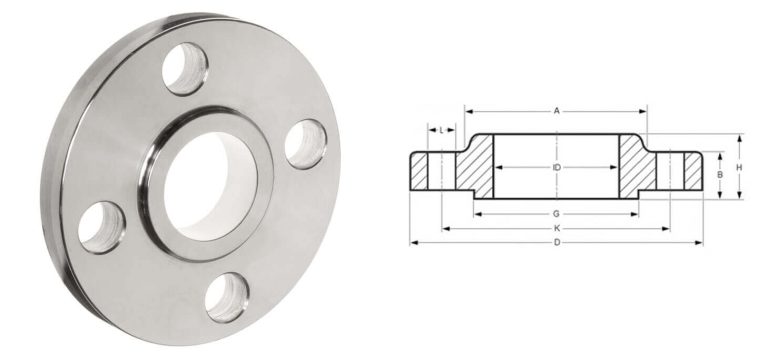

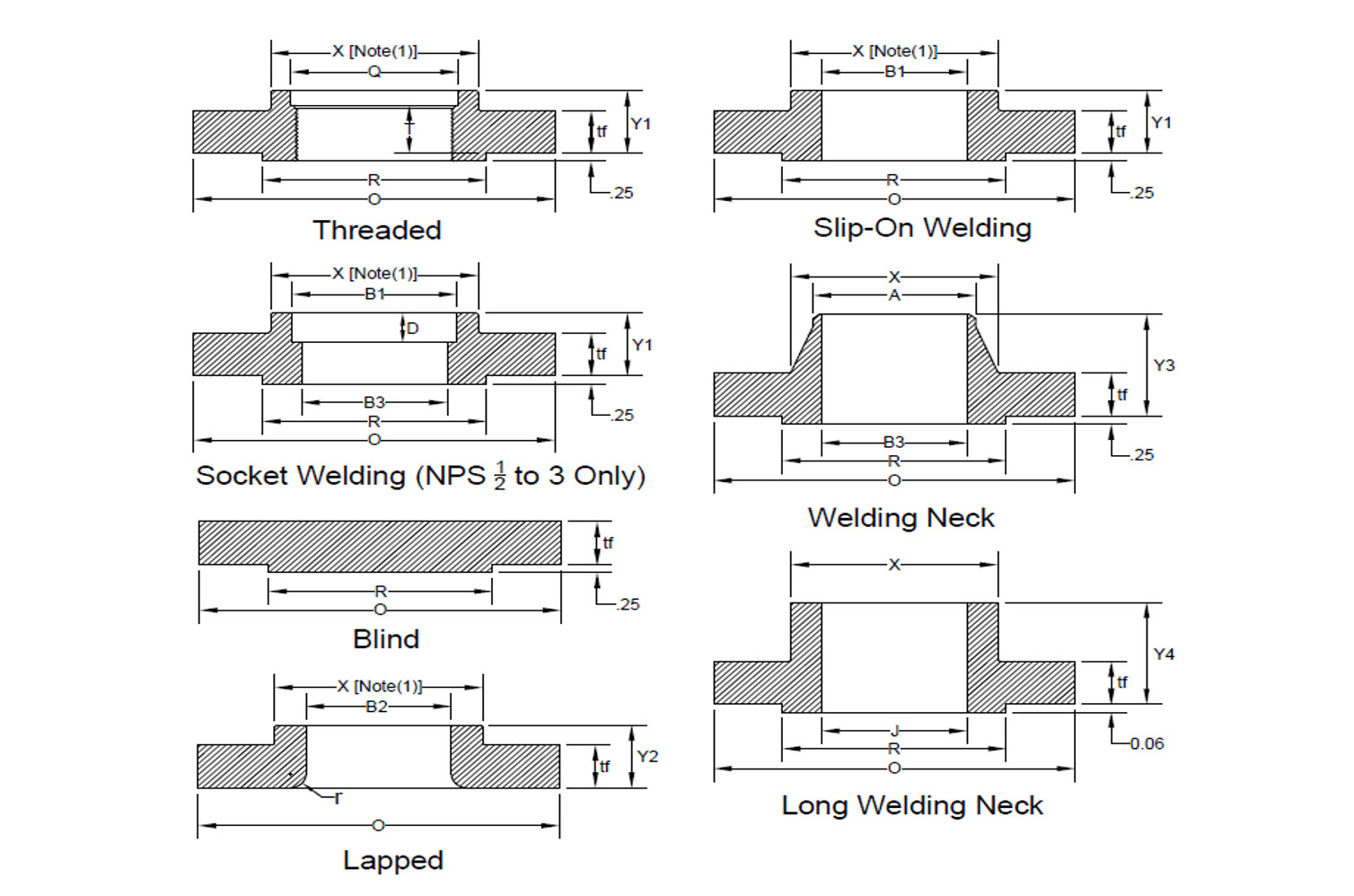

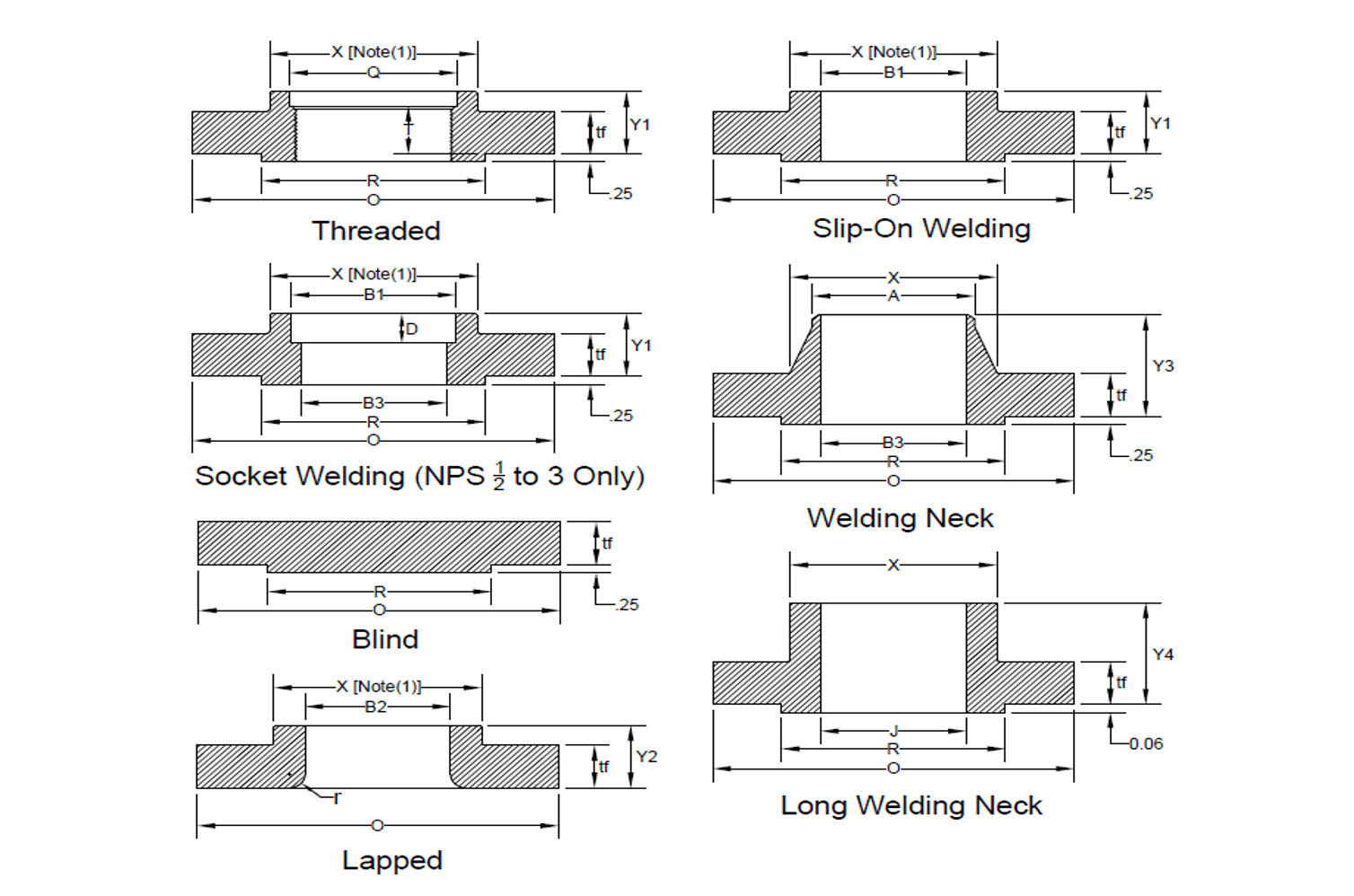

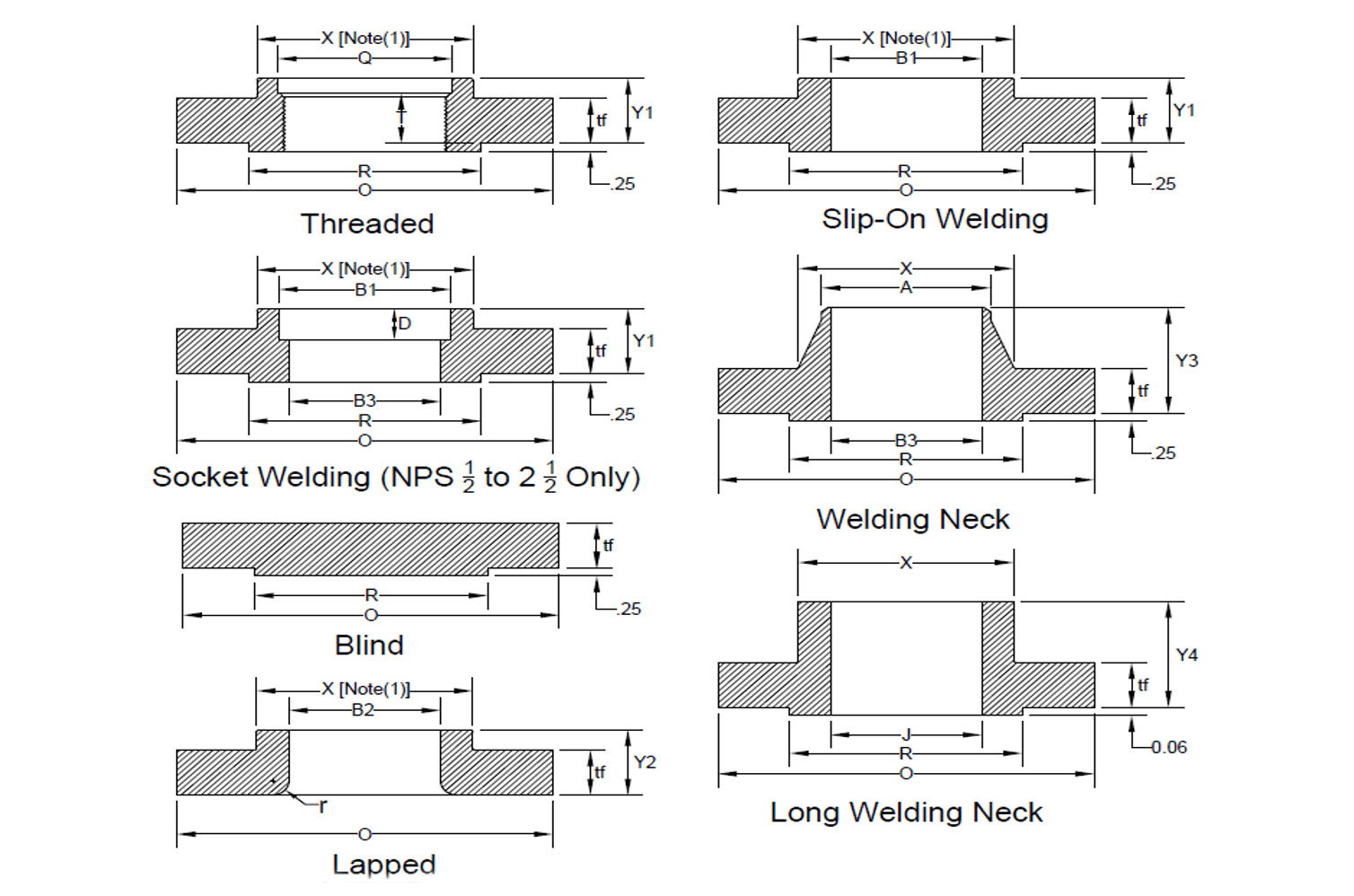

Weld Neck Flanges

Weld neck flanges have a long, tapered hub that’s butt-welded to the pipe. This smooth join spreads stress and keeps flow steady, so the joint stays strong under heat, pressure, and vibration.

Use when: lines run hot or at high pressure, or where failure isn’t an option—steam lines, refineries, chemical plants, offshore piping. Great fatigue resistance and ideal for frequent temperature cycles.

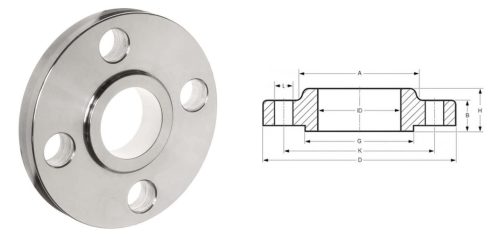

Slip-On Flanges

These slide over the pipe and are fillet-welded on the inside and outside. They’re easy to fit and align, which saves time in the field. Strength is lower than a weld neck, but good enough for many services.

Use when: low-to-medium pressure duties such as cooling water, fire-fighting mains, compressed air, general utilities. A cost-friendly choice for larger sizes.

Blind Flanges

A blind flange is a solid plate with bolt holes. It closes off the end of a pipe, valve, or vessel nozzle. You can remove it later for access.

Use when: you need a safe, leak-tight “stop” or test point—pressure testing spools, isolating sections for maintenance, future tie-ins.

Socket Weld Flanges

These have a recess that the pipe sits in, then you add a single fillet weld around the outside. The bore alignment is easy and the joint is quite strong on small sizes.

Use when: small-bore, high-pressure lines—hydraulic lines, short steam drops, instrument air. Avoid in services prone to crevice corrosion.

Threaded Flanges

Also called screwed flanges, these connect to threaded pipe with no welding. That’s handy in areas where hot work isn’t allowed.

Use when: low-pressure, non-critical lines or temporary hook-ups, and in flammable zones where welding is risky. Not for high temperature or heavy vibration.

Lap Joint Flanges

A lap joint is a two-piece setup: a stub end is welded to the pipe, and a loose (free-rotating) backing flange sits behind it. Only the stub end touches the fluid.

Use when: you need fast alignment and frequent dismantling—tank farms, systems with liners, or when using expensive alloys (the stub end is alloy; the backing flange can be carbon steel to save cost).

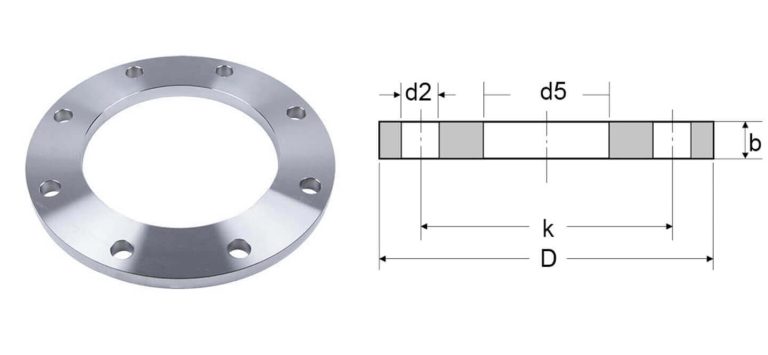

Plate Flanges

Cut from plate with a flat face and bolt holes, then welded to the pipe. Simple, robust, and economical for many services.

Use when: low-pressure water lines, HVAC, compressed air, and structural connections where budgets matter and conditions are mild.

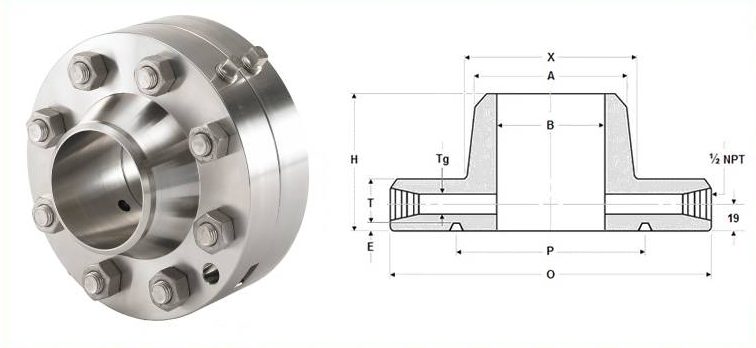

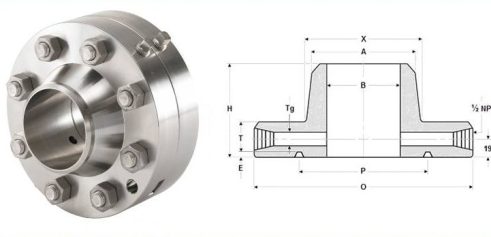

Orifice Flanges

Supplied as a matched pair with pressure tapping ports, these hold an orifice plate to measure flow using differential pressure. They often include jack screws for easy plate removal.

Use when: you need accurate flow measurement on process lines feeding DP transmitters—oil & gas, power, and chemical plants. Requires straight runs of pipe upstream/downstream for best accuracy.

Weld Neck Flanges

Weld neck flanges have a long, tapered hub that’s butt-welded to the pipe. This smooth join spreads stress and keeps flow steady, so the joint stays strong under heat, pressure, and vibration.

Use when: lines run hot or at high pressure, or where failure isn’t an option—steam lines, refineries, chemical plants, offshore piping. Great fatigue resistance and ideal for frequent temperature cycles.

Slip-On Flanges

These slide over the pipe and are fillet-welded on the inside and outside. They’re easy to fit and align, which saves time in the field. Strength is lower than a weld neck, but good enough for many services.

Use when: low-to-medium pressure duties such as cooling water, fire-fighting mains, compressed air, general utilities. A cost-friendly choice for larger sizes.

Blind Flanges

A blind flange is a solid plate with bolt holes. It closes off the end of a pipe, valve, or vessel nozzle. You can remove it later for access.

Use when: you need a safe, leak-tight “stop” or test point—pressure testing spools, isolating sections for maintenance, future tie-ins.

Threaded Flanges

Also called screwed flanges, these connect to threaded pipe with no welding. That’s handy in areas where hot work isn’t allowed.

Use when: low-pressure, non-critical lines or temporary hook-ups, and in flammable zones where welding is risky. Not for high temperature or heavy vibration.

Lap Joint Flanges

A lap joint is a two-piece setup: a stub end is welded to the pipe, and a loose (free-rotating) backing flange sits behind it. Only the stub end touches the fluid.

Use when: you need fast alignment and frequent dismantling—tank farms, systems with liners, or when using expensive alloys (the stub end is alloy; the backing flange can be carbon steel to save cost).

Plate Flanges,

Cut from plate with a flat face and bolt holes, then welded to the pipe. Simple, robust, and economical for many services.

Use when: low-pressure water lines, HVAC, compressed air, and structural connections where budgets matter and conditions are mild.

Orifice Flanges

Supplied as a matched pair with pressure tapping ports, these hold an orifice plate to measure flow using differential pressure. They often include jack screws for easy plate removal.

Use when: you need accurate flow measurement on process lines feeding DP transmitters—oil & gas, power, and chemical plants. Requires straight runs of pipe upstream/downstream for best accuracy.

Quick selection tips

- High pressure/temperature or cyclic loads? Weld neck.

- Fast fit and fair cost? Slip-on.

- End closure or pressure test point? Blind.

- Small-bore, higher pressure? Socket weld.

- No hot work allowed? Threaded.

- Frequent dismantling/alignment or lined pipe? Lap joint.

- Budget, low pressure? Plate.

- Need flow measurement? Orifice pair.

Flanges Specifications

Flanges Standards

Flanges Size

| NPS | DN |

| 1 | 25 |

| 1 1/2 | 40 |

| 1 1/4 | 32 |

| 1/2 | 15 |

| 2 | 50 |

| 2 1/2 | 65 |

| 3 | 80 |

| 3/4 | 20 |

| 4 | 100 |

Flange Materials

Flanges are made from different materials to match the needs of piping systems. The choice of material depends on factors like pressure, temperature, and resistance to corrosion. The materials we offer for flanges commonly are

Super Duplex Steel Flanges

Flanges Pressure Rating

Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS

| ASME | Pressure Temperature Ratings For Flanges | ||||||

| Temperature °F | Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

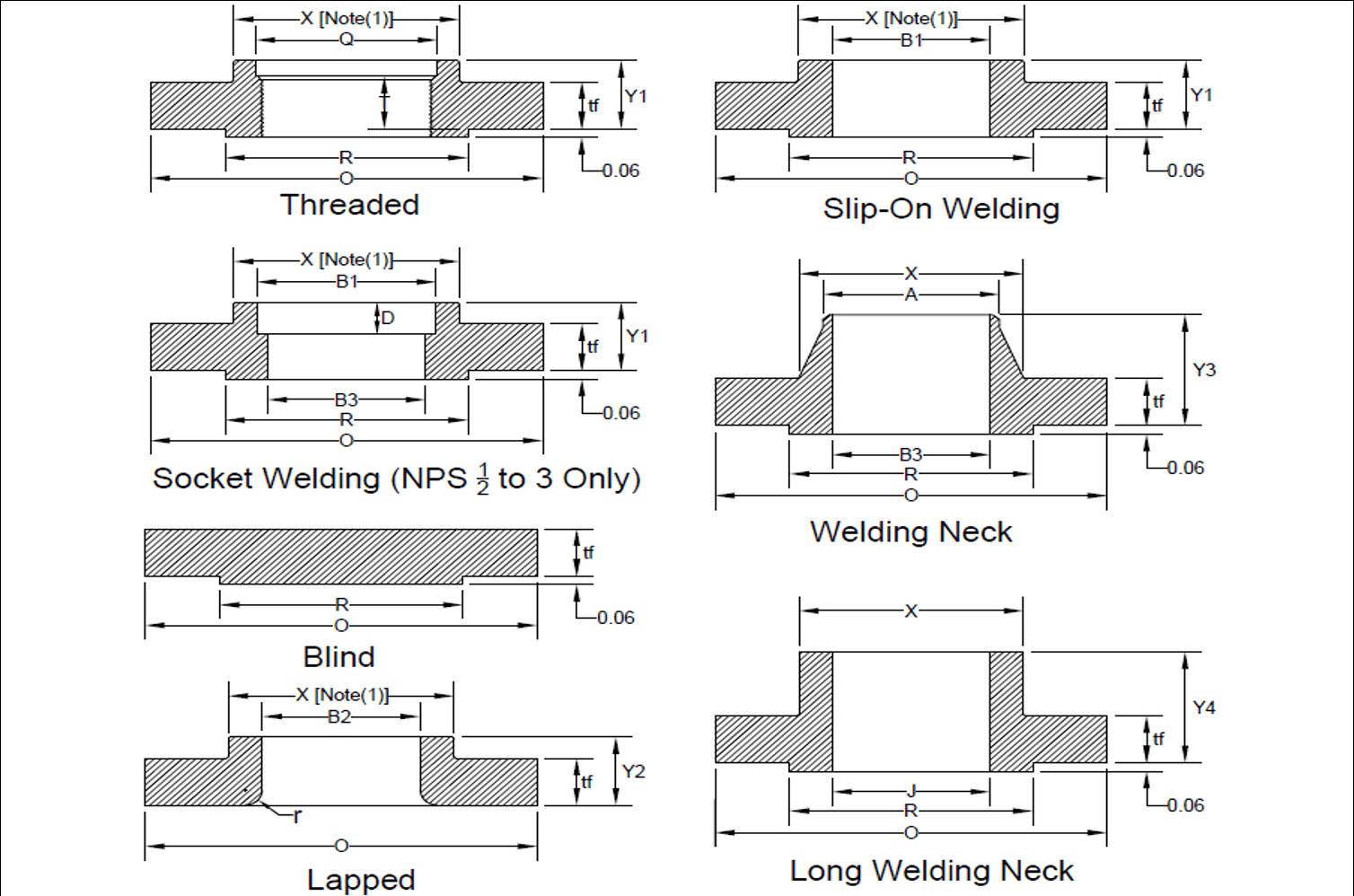

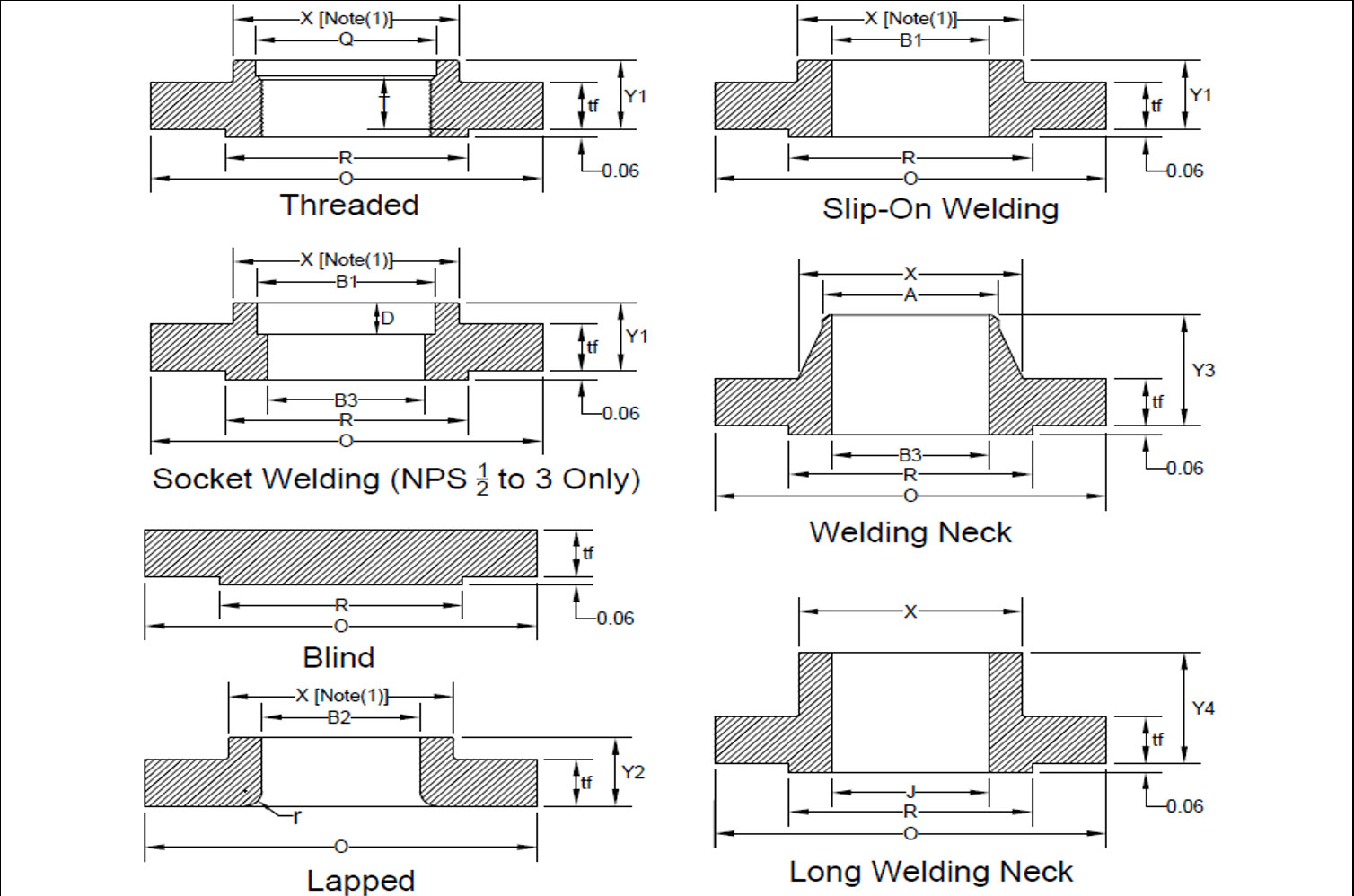

ASME B16 5 Flange Dimensions

Class 150 Flange Dimensions in mm

| Nominal Pipe Size/ Bore for LWN | Outside Diameter | Min. Thickness | Diameter of Raised Face | Min. Thickness Lap Joint | Diameter of Hub | Diameter Beginning of Chamfer Welding Neck | Threaded Slip-on Socket Welding | Lapped | Welding Neck | Long Welding Neck | Minimum Thread Length Threaded | Minimum Slip-On Socket Welding | Minimum Lapped | Welding Neck / Socket Welding | Corner Bore Radius of Lapped Flange and Pipe | Depth of Socket | Bolt Circle Dia | Number of Holes | Diameter of Holes |

| J | O | tf | R | tf | X | A | Y1 | Y2 | Y3 | Y4 | T | B1 | B2 | B3 | r | D | |||

| ½ | 3.50 | 0.38 | 1.38 | 0.44 | 1.19 | 0.84 | 0.56 | 0.62 | 1.81 | 9.00 | 0.62 | 0.88 | 0.90 | Note-3 | 0.12 | 0.38 | 2.38 | 4 | 0.63 |

| ¾ | 3.88 | 0.44 | 1.69 | 0.50 | 1.50 | 1.05 | 0.56 | 0.62 | 2.00 | 9.00 | 0.62 | 1.09 | 1.11 | Note-3 | 0.12 | 0.44 | 2.75 | 4 | 0.63 |

| 1 | 4.25 | 0.50 | 2.00 | 0.56 | 1.94 | 1.32 | 0.62 | 0.69 | 2.12 | 9.00 | 0.69 | 1.36 | 1.38 | Note-3 | 0.12 | 0.50 | 3.12 | 4 | 0.63 |

| 1¼ | 4.62 | 0.56 | 2.50 | 0.62 | 2.31 | 1.66 | 0.75 | 0.81 | 2.19 | 9.00 | 0.81 | 1.70 | 1.72 | Note-3 | 0.19 | 0.56 | 3.50 | 4 | 0.63 |

| 1½ | 5.00 | 0.62 | 2.88 | 0.69 | 2.56 | 1.90 | 0.81 | 0.88 | 2.38 | 9.00 | 0.88 | 1.95 | 1.97 | Note-3 | 0.25 | 0.62 | 3.88 | 4 | 0.63 |

| 2 | 6.00 | 0.69 | 3.62 | 0.75 | 3.06 | 2.38 | 0.94 | 1.00 | 2.44 | 9.00 | 1.00 | 2.44 | 2.46 | Note-3 | 0.31 | 0.69 | 4.75 | 4 | 0.75 |

| 2½ | 7.00 | 0.81 | 4.12 | 0.88 | 3.56 | 2.88 | 1.06 | 1.12 | 2.69 | 9.00 | 1.12 | 2.94 | 2.97 | Note-3 | 0.31 | 0.75 | 5.50 | 4 | 0.75 |

| 3 | 7.50 | 0.88 | 5.00 | 0.94 | 4.25 | 3.50 | 1.12 | 1.19 | 2.69 | 9.00 | 1.19 | 3.57 | 3.60 | Note-3 | 0.38 | 0.81 | 6.00 | 4 | 0.75 |

| 3½ | 8.50 | 0.88 | 5.50 | 0.94 | 4.81 | 4.00 | 1.19 | 1.25 | 2.75 | 9.00 | 1.25 | 4.07 | 4.10 | Note-3 | 0.38 | - | 7.00 | 8 | 0.75 |

| 4 | 9.00 | 0.88 | 6.19 | 0.94 | 5.31 | 4.50 | 1.25 | 1.31 | 2.94 | Note-3 | 1.31 | 4.57 | 4.60 | Note-3 | 0.44 | - | 7.50 | 8 | 0.75 |

| 5 | 10.00 | 0.88 | 7.31 | 0.94 | 6.44 | 5.56 | 1.38 | 1.44 | 3.44 | 12.00 | 1.44 | 5.66 | 5.69 | Note-3 | 0.44 | - | 8.50 | 8 | 0.88 |

| 6 | 11.00 | 0.94 | 8.50 | 1.00 | 7.56 | 6.63 | 1.50 | 1.56 | 3.44 | 12.00 | 1.56 | 6.72 | 6.75 | Note-3 | 0.50 | - | 9.50 | 8 | 0.88 |

| 8 | 13.50 | 1.06 | 10.62 | 1.12 | 9.69 | 8.63 | 1.69 | 1.75 | 3.94 | 12.00 | 1.75 | 8.72 | 8.75 | Note-3 | 0.50 | - | 11.75 | 8 | 0.88 |

| 10 | 16.00 | 1.12 | 12.75 | 1.19 | 12.00 | 10.75 | 1.88 | 1.94 | 3.94 | 12.00 | 1.94 | 10.88 | 10.92 | Note-3 | 0.50 | - | 14.25 | 12 | 1.00 |

| 12 | 19.00 | 1.19 | 15.00 | 1.25 | 14.38 | 12.75 | 2.12 | 2.19 | 4.44 | 12.00 | 2.19 | 12.88 | 12.92 | Note-3 | 0.50 | - | 17.00 | 12 | 1.00 |

| 14 | 21.00 | 1.31 | 16.25 | 1.38 | 15.75 | 14.00 | 2.19 | 3.12 | 4.94 | 12.00 | 2.25 | 14.14 | 14.18 | Note-3 | 0.50 | - | 18.75 | 12 | 1.13 |

| 16 | 23.50 | 1.38 | 18.50 | 1.44 | 18.00 | 16.00 | 2.44 | 3.44 | 4.94 | 12.00 | 2.50 | 16.16 | 16.19 | Note-3 | 0.50 | - | 21.25 | 16 | 1.13 |

| 18 | 25.00 | 1.50 | 21.00 | 1.56 | 19.88 | 18.00 | 2.62 | 3.81 | 5.44 | 12.00 | 2.69 | 18.18 | 18.20 | Note-3 | 0.50 | - | 22.75 | 16 | 1.25 |

| 20 | 27.50 | 1.62 | 23.00 | 1.69 | 22.00 | 20.00 | 2.81 | 4.06 | 5.62 | 12.00 | 2.88 | 20.20 | 20.25 | Note-3 | 0.50 | - | 25.00 | 20 | 1.25 |

| 22 | 29.50 | 1.75 | 25.25 | 1.81 | 24.00 | 22.00 | 3.06 | 4.25 | 5.82 | 12.00 | - | 22.22 | 22.25 | Note-3 | 0.50 | - | 27.25 | 20 | 1.38 |

| 24 | 32.00 | 1.81 | 27.25 | 1.88 | 26.12 | 24.00 | 3.19 | 4.38 | 5.94 | 12.00 | 3.25 | 24.25 | 24.25 | Note-3 | 0.50 | - | 29.50 | 20 | 1.38 |

|

Notes: |

|||||||||||||||||||

Class 300 Flange Dimensions in mm

| Nominal Pipe Size/ Bore for LWN | Outside Diameter | Min. Thickness | Diameter of Raised Face | Min. Thickness Lap Joint | Diameter of Hub | Diameter Beginning of Chamefer Welding Neck | Threaded Slip-on Socket Welding | Lapped | Welding Neck | Long Welding Neck | Minimum Thread Length Threaded | Minimum Slip-On Socket Welding | Minimum Lapped | Welding Neck / Socket Welding | Corner Bore Radius of Lapped Flange and Pipe | Depth of Socket | Minimum Counter-bore Threaded Flange | Bolt Circle Dia | Number of Holes | Diameter of Holes |

| J | O | tf | R | tf | X | A | Y1 | Y2 | Y3 | Y4 | T | B1 | B2 | B3 | r | D | Q | |||

| ½ | 3.75 | 0.50 | 1.38 | 0.56 | 1.50 | 0.84 | 0.81 | 0.88 | 2.00 | 9.00 | 0.62 | 0.88 | 0.90 | Note-3 | 0.12 | 0.38 | 0.93 | 2.62 | 4 | 0.63 |

| ¾ | 4.62 | 0.56 | 1.69 | 0.62 | 1.88 | 1.05 | 0.94 | 1.00 | 2.19 | 9.00 | 0.62 | 1.09 | 1.11 | Note-3 | 0.12 | 0.44 | 1.14 | 3.25 | 4 | 0.75 |

| 1 | 4.88 | 0.62 | 2.00 | 0.69 | 2.12 | 1.32 | 1.00 | 1.06 | 2.38 | 9.00 | 0.69 | 1.36 | 1.38 | Note-3 | 0.12 | 0.50 | 1.41 | 3.50 | 4 | 0.75 |

| 1¼ | 5.25 | 0.69 | 2.50 | 0.75 | 2.50 | 1.66 | 1.00 | 1.06 | 2.50 | 9.00 | 0.81 | 1.70 | 1.72 | Note-3 | 0.19 | 0.56 | 1.75 | 3.88 | 4 | 0.75 |

| 1½ | 6.12 | 0.75 | 2.88 | 0.81 | 2.75 | 1.90 | 1.13 | 1.19 | 2.63 | 9.00 | 0.88 | 1.95 | 1.97 | Note-3 | 0.25 | 0.62 | 1.98 | 4.50 | 4 | 0.88 |

| 2 | 6.50 | 0.81 | 3.62 | 0.88 | 3.31 | 2.38 | 1.25 | 1.31 | 2.69 | 9.00 | 1.12 | 2.44 | 2.46 | Note-3 | 0.31 | 0.69 | 2.50 | 5.00 | 8 | 0.75 |

| 2½ | 7.50 | 0.94 | 4.12 | 1.00 | 3.94 | 2.88 | 1.44 | 1.50 | 2.94 | 9.00 | 1.25 | 2.94 | 2.97 | Note-3 | 0.31 | 0.75 | 3.00 | 5.88 | 8 | 0.88 |

| 3 | 8.25 | 1.06 | 5.00 | 1.12 | 4.62 | 3.50 | 1.63 | 1.69 | 3.06 | 9.00 | 1.25 | 3.57 | 3.60 | Note-3 | 0.38 | 0.81 | 3.63 | 6.62 | 8 | 0.88 |

| 3½ | 9.00 | 1.12 | 5.50 | 1.19 | 5.25 | 4.00 | 1.69 | 1.75 | 3.13 | 9.00 | 1.44 | 4.07 | 4.10 | Note-3 | 0.38 | - | 4.13 | 7.25 | 8 | 0.88 |

| 4 | 10.00 | 1.19 | 6.19 | 1.25 | 5.75 | 4.50 | 1.82 | 1.88 | 3.32 | Note-3 | 1.44 | 4.57 | 4.60 | Note-3 | 0.44 | - | 4.63 | 7.88 | 8 | 0.88 |

| 5 | 11.00 | 1.31 | 7.31 | 1.38 | 7.00 | 5.56 | 1.94 | 2.00 | 3.82 | 12.00 | 1.69 | 5.66 | 5.69 | Note-3 | 0.44 | - | 5.69 | 9.25 | 8 | 0.88 |

| 6 | 12.50 | 1.38 | 8.50 | 1.44 | 8.12 | 6.63 | 2.00 | 2.06 | 3.82 | 12.00 | 1.81 | 6.72 | 6.75 | Note-3 | 0.50 | - | 6.75 | 10.62 | 12 | 0.88 |

| 8 | 15.00 | 1.56 | 10.62 | 1.62 | 10.25 | 8.63 | 2.38 | 2.44 | 4.32 | 12.00 | 2.00 | 8.72 | 8.75 | Note-3 | 0.50 | - | 8.75 | 13.00 | 12 | 1.00 |

| 10 | 17.50 | 1.81 | 12.75 | 1.88 | 12.62 | 10.75 | 2.56 | 3.75 | 4.56 | 12.00 | 2.19 | 10.88 | 10.92 | Note-3 | 0.50 | - | 10.88 | 15.25 | 16 | 1.13 |

| 12 | 20.50 | 1.94 | 15.00 | 2.00 | 14.75 | 12.75 | 2.82 | 4.00 | 5.06 | 12.00 | 2.38 | 12.88 | 12.92 | Note-3 | 0.50 | - | 12.94 | 17.75 | 16 | 1.25 |

| 14 | 23.00 | 2.06 | 16.25 | 2.12 | 16.75 | 14.00 | 2.94 | 4.38 | 5.56 | 12.00 | 2.50 | 14.14 | 14.18 | Note-3 | 0.50 | - | 14.19 | 20.25 | 20 | 1.25 |

| 16 | 25.50 | 2.19 | 18.50 | 2.25 | 19.00 | 16.00 | 3.19 | 4.75 | 5.69 | 12.00 | 2.69 | 16.16 | 16.19 | Note-3 | 0.50 | - | 16.19 | 22.50 | 20 | 1.38 |

| 18 | 28.00 | 2.31 | 21.00 | 2.38 | 21.00 | 18.00 | 3.44 | 5.12 | 6.19 | 12.00 | 2.75 | 18.18 | 18.20 | Note-3 | 0.50 | - | 18.19 | 24.75 | 24 | 1.38 |

| 20 | 30.50 | 2.44 | 23.00 | 2.50 | 23.12 | 20.00 | 3.69 | 5.50 | 6.32 | 12.00 | 2.88 | 20.20 | 20.25 | Note-3 | 0.50 | - | 20.19 | 27.00 | 24 | 1.38 |

| 22 | 33.00 | 2.56 | 25.25 | 2.62 | 25.25 | 22.00 | 3.94 | 5.69 | 6.44 | 12.00 | - | 22.22 | 22.25 | Note-3 | 0.50 | - | - | 29.25 | 24 | 1.63 |

| 24 | 36.00 | 2.69 | 27.25 | 2.75 | 27.62 | 24.00 | 4.13 | 6.00 | 6.56 | 12.00 | 3.25 | 24.25 | 24.25 | Note-3 | 0.50 | - | 24.19 | 32.00 | 24 | 1.63 |

|

Notes: |

||||||||||||||||||||

Class 400 Flange Dimensions in mm

| Nominal Pipe Size/ Bore for LWN | Outside Diameter | Min. Thickness | Diameter of Raised Face | Diameter of Hub | Diameter Beginning of Chamefer Welding Neck | Threaded Slip-on Socket Welding | Lapped | Welding Neck | Long Welding Neck | Minimum Thread Length Threaded | Minimum Slip-On Socket Welding | Minimum Lapped | Welding Neck / Socket Welding | Corner Bore Radius of Lapped Flange and Pipe | Depth of Socket | Minimum Counter-bore Threaded Flange | Bolt Circle Dia | Number of Holes | Diameter of Holes |

| J | O | tf | R | X | A | Y1 | Y2 | Y3 | Y4 | T | B1 | B2 | B3 | r | D | Q | |||

| ½ | 3.75 | 0.56 | 1.38 | 1.50 | 0.84 | 0.88 | 0.88 | 2.06 | 9.00 | 0.62 | 0.88 | 0.90 | Note-3 | 0.12 | 0.38 | 0.93 | 2.62 | 4 | 0.63 |

| ¾ | 4.62 | 0.62 | 1.69 | 1.88 | 1.05 | 1.00 | 1.00 | 2.25 | 9.00 | 0.62 | 1.09 | 1.11 | Note-3 | 0.12 | 0.44 | 1.14 | 3.25 | 4 | 0.75 |

| 1 | 4.88 | 0.69 | 2.00 | 2.12 | 1.32 | 1.06 | 1.06 | 2.44 | 9.00 | 0.69 | 1.36 | 1.38 | Note-3 | 0.12 | 0.50 | 1.41 | 3.50 | 4 | 0.75 |

| 1¼ | 5.25 | 0.81 | 2.50 | 2.50 | 1.66 | 1.12 | 1.12 | 2.62 | 9.00 | 0.81 | 1.70 | 1.72 | Note-3 | 0.19 | 0.56 | 1.75 | 3.88 | 4 | 0.75 |

| 1½ | 6.12 | 0.88 | 2.88 | 2.75 | 1.90 | 1.25 | 1.25 | 2.75 | 9.00 | 0.88 | 1.95 | 1.97 | Note-3 | 0.25 | 0.62 | 1.99 | 4.50 | 4 | 0.88 |

| 2 | 6.50 | 1.00 | 3.62 | 3.31 | 2.38 | 1.44 | 1.44 | 2.88 | 9.00 | 1.12 | 2.44 | 2.46 | Note-3 | 0.31 | 0.69 | 2.50 | 5.00 | 8 | 0.75 |

| 2½ | 7.50 | 1.12 | 4.12 | 3.94 | 2.88 | 1.62 | 1.62 | 3.12 | 9.00 | 1.25 | 2.94 | 2.97 | Note-3 | 0.31 | 0.75 | 3.00 | 5.88 | 8 | 0.88 |

| 3 | 8.25 | 1.25 | 5.00 | 4.62 | 3.50 | 1.81 | 1.81 | 3.25 | 9.00 | 1.38 | 3.57 | 3.60 | Note-3 | 0.38 | 0.81 | 3.63 | 6.62 | 8 | 0.88 |

| 3½ | 9.00 | 1.38 | 5.50 | 5.25 | 4.00 | 1.94 | 1.94 | 3.38 | 9.00 | 1.56 | 4.07 | 4.10 | Note-3 | 0.38 | - | 4.13 | 7.25 | 8 | 1.00 |

| 4 | 10.00 | 1.38 | 6.19 | 5.75 | 4.50 | 2.00 | 2.00 | 3.50 | Note-3 | 1.44 | 4.57 | 4.60 | Note-3 | 0.44 | - | 4.63 | 7.88 | 8 | 1.00 |

| 5 | 11.00 | 1.50 | 7.31 | 7.00 | 5.56 | 2.12 | 2.12 | 4.00 | 12.00 | 1.69 | 5.66 | 5.69 | Note-3 | 0.44 | - | 5.69 | 9.25 | 8 | 1.00 |

| 6 | 12.50 | 1.62 | 8.50 | 8.12 | 6.63 | 2.25 | 2.25 | 4.06 | 12.00 | 1.81 | 6.72 | 6.75 | Note-3 | 0.50 | - | 6.75 | 10.62 | 12 | 1.00 |

| 8 | 15.00 | 1.88 | 10.62 | 10.25 | 8.63 | 2.69 | 2.69 | 4.62 | 12.00 | 2.00 | 8.72 | 8.75 | Note-3 | 0.50 | - | 8.75 | 13.00 | 12 | 1.13 |

| 10 | 17.50 | 2.12 | 12.75 | 12.62 | 10.75 | 2.88 | 4.00 | 4.88 | 12.00 | 2.19 | 10.88 | 10.92 | Note-3 | 0.50 | - | 10.88 | 15.25 | 16 | 1.25 |

| 12 | 20.50 | 2.25 | 15.00 | 14.75 | 12.75 | 3.12 | 4.25 | 5.38 | 12.00 | 2.38 | 12.88 | 12.92 | Note-3 | 0.50 | - | 12.94 | 17.75 | 16 | 1.38 |

| 14 | 23.00 | 2.38 | 16.25 | 16.75 | 14.00 | 3.31 | 4.62 | 5.88 | 12.00 | 2.50 | 14.14 | 14.18 | Note-3 | 0.50 | - | 14.19 | 20.25 | 20 | 1.38 |

| 16 | 25.50 | 2.50 | 18.50 | 19.00 | 16.00 | 3.69 | 5.00 | 6.00 | 12.00 | 2.69 | 16.16 | 16.19 | Note-3 | 0.50 | - | 16.19 | 22.50 | 20 | 1.50 |

| 18 | 28.00 | 2.62 | 21.00 | 21.00 | 18.00 | 3.88 | 5.38 | 6.50 | 12.00 | 2.75 | 18.18 | 18.20 | Note-3 | 0.50 | - | 18.19 | 24.75 | 24 | 1.50 |

| 20 | 30.50 | 2.75 | 23.00 | 23.12 | 20.00 | 4.00 | 5.75 | 6.62 | 12.00 | 2.88 | 20.20 | 20.25 | Note-3 | 0.50 | - | 20.19 | 27.00 | 24 | 1.63 |

| 22 | 33.00 | 2.88 | 25.25 | 25.25 | 22.00 | 4.25 | 6.00 | 6.75 | 12.00 | - | 22.22 | 22.25 | Note-3 | 0.50 | - | - | 29.25 | 24 | 1.75 |

| 24 | 36.00 | 3.00 | 27.25 | 27.62 | 24.00 | 4.50 | 6.25 | 6.88 | 12.00 | 3.25 | 24.25 | 24.25 | Note-3 | 0.50 | - | 24.19 | 32.00 | 24 | 1.88 |

|

Notes: |

|||||||||||||||||||

Class 600 Flange Dimensions in mm

| Nominal Pipe Size/ Bore for LWN | Outside Diameter | Min. Thickness | Diameter of Raised Face | Diameter of Hub | Diameter Beginning of Chamefer Welding Neck | Threaded Slip-on Socket Welding | Lapped | Welding Neck | Long Welding Neck | Minimum Thread Length Threaded | Minimum Slip-On Socket Welding | Minimum Lapped | Welding Neck / Socket Welding | Corner Bore Radius of Lapped Flange and Pipe | Depth of Socket | Minimum Counter-bore Threaded Flange | Bolt Circle Dia | Number of Holes | Diameter of Holes |

| J | O | tf | R | X | A | Y1 | Y2 | Y3 | Y4 | T | B1 | B2 | B3 | r | D | Q | |||

| ½ | 3.75 | 0.56 | 1.38 | 1.50 | 0.84 | 0.88 | 0.88 | 2.06 | 9.00 | 0.62 | 0.88 | 0.90 | Note-3 | 0.12 | 0.38 | 0.93 | 2.62 | 4 | 0.63 |

| ¾ | 4.62 | 0.62 | 1.69 | 1.88 | 1.05 | 1.00 | 1.00 | 2.25 | 9.00 | 0.62 | 1.09 | 1.11 | Note-3 | 0.12 | 0.44 | 1.14 | 3.25 | 4 | 0.75 |

| 1 | 4.88 | 0.69 | 2.00 | 2.12 | 1.32 | 1.06 | 1.06 | 2.44 | 9.00 | 0.69 | 1.36 | 1.38 | Note-3 | 0.12 | 0.50 | 1.41 | 3.50 | 4 | 0.75 |

| 1¼ | 5.25 | 0.81 | 2.50 | 2.50 | 1.66 | 1.12 | 1.12 | 2.62 | 9.00 | 0.81 | 1.70 | 1.72 | Note-3 | 0.19 | 0.56 | 1.75 | 3.88 | 4 | 0.75 |

| 1½ | 6.12 | 0.88 | 2.88 | 2.75 | 1.90 | 1.25 | 1.25 | 2.75 | 9.00 | 0.88 | 1.95 | 1.97 | Note-3 | 0.25 | 0.62 | 1.99 | 4.50 | 4 | 0.88 |

| 2 | 6.50 | 1.00 | 3.62 | 3.31 | 2.38 | 1.44 | 1.44 | 2.88 | 9.00 | 1.12 | 2.44 | 2.46 | Note-3 | 0.31 | 0.69 | 2.50 | 5.00 | 8 | 0.75 |

| 2½ | 7.50 | 1.12 | 4.12 | 3.94 | 2.88 | 1.62 | 1.62 | 3.12 | 9.00 | 1.25 | 2.94 | 2.97 | Note-3 | 0.31 | 0.75 | 3.00 | 5.88 | 8 | 0.88 |

| 3 | 8.25 | 1.25 | 5.00 | 4.62 | 3.50 | 1.81 | 1.81 | 3.25 | 9.00 | 1.38 | 3.57 | 3.60 | Note-3 | 0.38 | 0.81 | 3.63 | 6.62 | 8 | 0.88 |

| 3½ | 9.00 | 1.38 | 5.50 | 5.25 | 4.00 | 1.94 | 1.94 | 3.38 | 9.00 | 1.56 | 4.07 | 4.10 | Note-3 | 0.38 | - | 4.13 | 7.25 | 8 | 1.00 |

| 4 | 10.75 | 1.50 | 6.19 | 6.00 | 4.50 | 2.12 | 2.12 | 4.00 | Note-3 | 1.62 | 4.57 | 4.60 | Note-3 | 0.44 | - | 4.63 | 8.50 | 8 | 1.00 |

| 5 | 13.00 | 1.75 | 7.31 | 7.44 | 5.56 | 2.38 | 2.38 | 4.50 | 12.00 | 1.88 | 5.66 | 5.69 | Note-3 | 0.44 | - | 5.69 | 10.50 | 8 | 1.12 |

| 6 | 14.00 | 1.88 | 8.50 | 8.75 | 6.63 | 2.62 | 2.62 | 4.62 | 12.00 | 2.00 | 6.72 | 6.75 | Note-3 | 0.50 | - | 6.75 | 11.50 | 12 | 1.12 |

| 8 | 16.50 | 2.19 | 10.62 | 10.75 | 8.63 | 3.00 | 3.00 | 5.25 | 12.00 | 2.25 | 8.72 | 8.75 | Note-3 | 0.50 | - | 8.75 | 13.75 | 12 | 1.25 |

| 10 | 20.00 | 2.50 | 12.75 | 13.50 | 10.75 | 3.38 | 4.38 | 6.00 | 12.00 | 2.56 | 10.88 | 10.92 | Note-3 | 0.50 | - | 10.88 | 17.00 | 16 | 1.38 |

| 12 | 22.00 | 2.62 | 15.00 | 15.75 | 12.75 | 3.62 | 4.62 | 6.12 | 12.00 | 2.75 | 12.88 | 12.92 | Note-3 | 0.50 | - | 12.94 | 19.25 | 20 | 1.38 |

| 14 | 23.75 | 2.75 | 16.25 | 17.00 | 14.00 | 3.69 | 5.00 | 6.50 | 12.00 | 2.88 | 14.14 | 14.18 | Note-3 | 0.50 | - | 14.19 | 20.75 | 20 | 1.50 |

| 16 | 27.00 | 3.00 | 18.50 | 19.50 | 16.00 | 4.19 | 5.50 | 7.00 | 12.00 | 3.06 | 16.16 | 16.19 | Note-3 | 0.50 | - | 16.19 | 23.75 | 20 | 1.62 |

| 18 | 29.25 | 3.25 | 21.00 | 21.50 | 18.00 | 4.62 | 6.00 | 7.25 | 12.00 | 3.12 | 18.18 | 18.20 | Note-3 | 0.50 | - | 18.19 | 25.75 | 20 | 1.75 |

| 20 | 32.00 | 3.50 | 23.00 | 24.00 | 20.00 | 5.00 | 6.50 | 7.50 | 12.00 | 3.25 | 20.20 | 20.25 | Note-3 | 0.50 | - | 20.19 | 28.50 | 24 | 1.75 |

| 22 | 34.25 | 3.75 | 25.25 | 26.25 | 22.00 | 5.25 | 6.88 | 7.75 | 12.00 | - | 22.22 | 22.25 | Note-3 | 0.50 | - | - | 30.63 | 24 | 1.88 |

| 24 | 37.00 | 4.00 | 27.25 | 28.25 | 24.00 | 5.50 | 7.25 | 8.00 | 12.00 | 3.62 | 24.25 | 24.25 | Note-3 | 0.50 | - | 24.19 | 33.00 | 24 | 2.00 |

|

Notes: |

|||||||||||||||||||

Class 900 Flange Dimensions in mm

| Nominal Pipe Size/ Bore for LWN | Outside Diameter | Min. Thickness | Diameter of Raised Face | Diameter of Hub | Diameter Beginning of Chamefer Welding Neck | Threaded Slip-on Socket Welding | Lapped | Welding Neck | Long Welding Neck | Minimum Thread Length Threaded | Minimum Slip-On Socket Welding | Minimum Lapped | Welding Neck / Socket Welding | Corner Bore Radius of Lapped Flange and Pipe | Depth of Socket | Minimum Counter-bore Threaded Flange | Bolt Circle Dia | Number of Holes | Diameter of Holes |

| J | O | tf | R | X | A | Y1 | Y2 | Y3 | Y4 | T | B1 | B2 | B3 | r | D | Q | |||

| ½ | 4.75 | 0.88 | 1.38 | 1.50 | 0.84 | 1.25 | 1.25 | 2.38 | 9.00 | 0.88 | 0.88 | 0.90 | Note-3 | 0.12 | 0.38 | 0.93 | 3.25 | 4 | 0.88 |

| ¾ | 5.12 | 1.00 | 1.69 | 1.75 | 1.05 | 1.38 | 1.38 | 2.75 | 9.00 | 1.00 | 1.09 | 1.11 | Note-3 | 0.12 | 0.44 | 1.14 | 3.50 | 4 | 0.88 |

| 1 | 5.88 | 1.12 | 2.00 | 2.06 | 1.32 | 1.62 | 1.62 | 2.88 | 9.00 | 1.12 | 1.36 | 1.38 | Note-3 | 0.12 | 0.50 | 1.41 | 4.00 | 4 | 1.00 |

| 1¼ | 6.25 | 1.12 | 2.50 | 2.50 | 1.66 | 1.62 | 1.62 | 2.88 | 9.00 | 1.19 | 1.70 | 1.72 | Note-3 | 0.19 | 0.56 | 1.75 | 4.38 | 4 | 1.00 |

| 1½ | 7.00 | 1.25 | 2.88 | 2.75 | 1.90 | 1.75 | 1.75 | 3.25 | 9.00 | 1.25 | 1.95 | 1.97 | Note-3 | 0.25 | 0.62 | 1.99 | 4.88 | 4 | 1.13 |

| 2 | 8.50 | 1.50 | 3.63 | 4.12 | 2.38 | 2.25 | 2.25 | 4.00 | 9.00 | 1.50 | 2.44 | 2.46 | Note-3 | 0.31 | 0.69 | 2.50 | 6.50 | 8 | 1.00 |

| 2½ | 9.62 | 1.62 | 4.13 | 4.88 | 2.88 | 2.50 | 2.50 | 4.12 | 9.00 | 1.88 | 2.94 | 2.97 | Note-3 | 0.31 | 0.75 | 3.00 | 7.50 | 8 | 1.13 |

| 3 | 9.50 | 1.50 | 5.00 | 5.00 | 3.50 | 2.12 | 2.12 | 4.00 | 9.00 | 1.62 | 3.57 | 3.60 | Note-3 | 0.38 | - | 3.63 | 7.50 | 8 | 1.00 |

| 4 | 11.50 | 1.75 | 6.19 | 6.25 | 4.50 | 2.75 | 2.75 | 4.50 | Note-3 | 1.88 | 4.57 | 4.60 | Note-3 | 0.44 | - | 4.63 | 9.25 | 8 | 1.25 |

| 5 | 13.75 | 2.00 | 7.31 | 7.50 | 5.56 | 3.12 | 3.12 | 5.00 | 12.00 | 2.12 | 5.66 | 5.69 | Note-3 | 0.44 | - | 5.69 | 11.00 | 8 | 1.38 |

| 6 | 15.00 | 2.19 | 8.50 | 9.25 | 6.63 | 3.38 | 3.38 | 5.50 | 12.00 | 2.25 | 6.72 | 6.75 | Note-3 | 0.50 | - | 6.75 | 12.50 | 12 | 1.25 |

| 8 | 18.50 | 2.50 | 10.62 | 11.75 | 8.63 | 4.00 | 4.50 | 6.38 | 12.00 | 2.50 | 8.72 | 8.75 | Note-3 | 0.50 | - | 8.75 | 15.50 | 12 | 1.50 |

| 10 | 21.50 | 2.75 | 12.75 | 14.50 | 10.75 | 4.25 | 5.00 | 7.25 | 12.00 | 2.81 | 10.88 | 10.92 | Note-3 | 0.50 | - | 10.88 | 18.50 | 16 | 1.50 |

| 12 | 24.00 | 3.12 | 15.00 | 16.50 | 12.75 | 4.62 | 5.62 | 7.88 | 12.00 | 3.00 | 12.88 | 12.92 | Note-3 | 0.50 | - | 12.94 | 21.00 | 20 | 1.50 |

| 14 | 25.25 | 3.38 | 16.25 | 17.75 | 14.00 | 5.12 | 6.12 | 8.38 | 12.00 | 3.25 | 14.14 | 14.18 | Note-3 | 0.50 | - | 14.19 | 22.00 | 20 | 1.63 |

| 16 | 27.75 | 3.50 | 18.50 | 20.00 | 16.00 | 5.25 | 6.50 | 8.50 | 12.00 | 3.38 | 16.16 | 16.19 | Note-3 | 0.50 | - | 16.19 | 24.25 | 20 | 1.75 |

| 18 | 31.00 | 4.00 | 21.00 | 22.25 | 18.00 | 6.00 | 7.50 | 9.00 | 12.00 | 3.50 | 18.18 | 18.20 | Note-3 | 0.50 | - | 18.19 | 27.00 | 20 | 2.00 |

| 20 | 33.75 | 4.25 | 23.00 | 24.50 | 20.00 | 6.25 | 8.25 | 9.75 | 12.00 | 3.62 | 20.20 | 20.25 | Note-3 | 0.50 | - | 20.19 | 29.50 | 20 | 2.13 |

| 24 | 41.00 | 5.50 | 27.25 | 29.50 | 24.00 | 8.00 | 10.50 | 11.50 | 12.00 | 4.00 | 24.25 | 24.25 | Note-3 | 0.50 | - | 24.19 | 35.50 | 20 | 2.63 |

|

Notes: |

|||||||||||||||||||

Class 1500 Flange Dimensions in mm

| Nominal Pipe Size/ Bore for LWN | Outside Diameter | Min. Thickness | Diameter of Raised Face | Diameter of Hub | Diameter Beginning of Chamefer Welding Neck | Threaded Slip-on Socket Welding | Lapped | Welding Neck | Long Welding Neck | Minimum Thread Length Threaded | Minimum Slip-On Socket Welding | Minimum Lapped | Welding Neck / Socket Welding | Corner Bore Radius of Lapped Flange and Pipe | Depth of Socket | Minimum Counter-bore Threaded Flange | Bolt Circle Dia | Number of Holes | Diameter of Holes |

| J | O | tf | R | X | A | Y1 | Y2 | Y3 | Y4 | T | B1 | B2 | B3 | r | D | Q | |||

| ½ | 4.75 | 0.88 | 1.38 | 1.50 | 0.84 | 1.25 | 1.25 | 2.38 | 9.00 | 0.88 | 0.88 | 0.90 | Note-3 | 0.12 | 0.38 | 0.93 | 3.25 | 4 | 0.88 |

| ¾ | 5.12 | 1.00 | 1.69 | 1.75 | 1.05 | 1.38 | 1.38 | 2.75 | 9.00 | 1.00 | 1.09 | 1.11 | Note-3 | 0.12 | 0.44 | 1.14 | 3.50 | 4 | 0.88 |

| 1 | 5.88 | 1.12 | 2.00 | 2.06 | 1.32 | 1.62 | 1.62 | 2.88 | 9.00 | 1.12 | 1.36 | 1.38 | Note-3 | 0.12 | 0.50 | 1.41 | 4.00 | 4 | 1.00 |

| 1¼ | 6.25 | 1.12 | 2.50 | 2.50 | 1.66 | 1.62 | 1.62 | 2.88 | 9.00 | 1.19 | 1.70 | 1.72 | Note-3 | 0.19 | 0.56 | 1.75 | 4.38 | 4 | 1.00 |

| 1½ | 7.00 | 1.25 | 2.88 | 2.75 | 1.90 | 1.75 | 1.75 | 3.25 | 9.00 | 1.25 | 1.95 | 1.97 | Note-3 | 0.25 | 0.62 | 1.99 | 4.88 | 4 | 1.13 |

| 2 | 8.50 | 1.50 | 3.62 | 4.12 | 2.38 | 2.25 | 2.25 | 4.00 | 9.00 | 1.50 | 2.44 | 2.46 | Note-3 | 0.31 | 0.69 | 2.50 | 6.50 | 8 | 1.00 |

| 2½ | 9.62 | 1.62 | 4.12 | 4.88 | 2.88 | 2.50 | 2.50 | 4.12 | 9.00 | 1.88 | 2.94 | 2.97 | Note-3 | 0.31 | 0.75 | 3.00 | 7.50 | 8 | 1.13 |

| 3 | 10.50 | 1.88 | 5.00 | 5.25 | 3.50 | - | 2.88 | 4.62 | 9.00 | - | - | 3.60 | Note-3 | 0.38 | - | - | 8.00 | 8 | 1.25 |

| 4 | 12.25 | 2.12 | 6.19 | 6.38 | 4.50 | - | 3.56 | 4.88 | Note-3 | - | - | 4.60 | Note-3 | 0.44 | - | - | 9.50 | 8 | 1.38 |

| 5 | 14.75 | 2.88 | 7.31 | 7.75 | 5.56 | - | 4.12 | 6.12 | 12.00 | - | - | 5.69 | Note-3 | 0.44 | - | - | 11.50 | 8 | 1.63 |

| 6 | 15.50 | 3.25 | 8.50 | 9.00 | 6.63 | - | 4.69 | 6.75 | 12.00 | - | - | 6.75 | Note-3 | 0.50 | - | - | 12.50 | 12 | 1.50 |

| 8 | 19.00 | 3.62 | 10.62 | 11.50 | 8.63 | - | 5.62 | 8.38 | 12.00 | - | - | 8.75 | Note-3 | 0.50 | - | - | 15.50 | 12 | 1.75 |

| 10 | 23.00 | 4.25 | 12.75 | 14.50 | 10.75 | - | 7.00 | 10.00 | 12.00 | - | - | 10.92 | Note-3 | 0.50 | - | - | 19.00 | 12 | 2.00 |

| 12 | 26.50 | 4.88 | 15.00 | 17.75 | 12.75 | - | 8.62 | 11.12 | 12.00 | - | - | 12.92 | Note-3 | 0.50 | - | - | 22.50 | 16 | 2.13 |

| 14 | 29.50 | 5.25 | 16.25 | 19.50 | 14.00 | - | 9.50 | 11.75 | 12.00 | - | - | 14.18 | Note-3 | 0.50 | - | - | 25.00 | 16 | 2.38 |

| 16 | 32.50 | 5.75 | 18.50 | 21.75 | 16.00 | - | 10.25 | 12.25 | 12.00 | - | - | 16.19 | Note-3 | 0.50 | - | - | 27.75 | 16 | 2.63 |

| 18 | 36.00 | 6.38 | 21.00 | 23.50 | 18.00 | - | 10.88 | 12.88 | 12.00 | - | - | 18.20 | Note-3 | 0.50 | - | - | 30.50 | 16 | 2.88 |

| 20 | 38.75 | 7.00 | 23.00 | 25.25 | 20.00 | - | 11.50 | 14.00 | 12.00 | - | - | 20.25 | Note-3 | 0.50 | - | - | 32.75 | 16 | 3.13 |

| 24 | 46.00 | 8.00 | 27.25 | 30.00 | 24.00 | - | 13.00 | 16.00 | 12.00 | - | - | 24.25 | Note-3 | 0.50 | - | - | 39.00 | 16 | 3.63 |

|

Notes: |

|||||||||||||||||||

Class 2500 Flange Dimensions in mm

| Nominal Pipe Size/ Bore for LWN | Outside Diameter | Min. Thickness | Diameter of Raised Face | Diameter of Hub | Hub Diameter Beginning of Chamefer Welding Neck | Threaded | Lapped | Welding Neck | Long Welding Neck | Minimum Thread Length Threaded | Minimum Lapped | Welding Neck | Corner Bore Radius of Lapped Flange and Pipe | Minimum Counter-bore Threaded Flange | Bolt Circle Dia | Number of Holes | Diameter of Holes | ||

| J | O | tf | R | X | A | Y1 | Y2 | Y3 | Y4 | T | B2 | B3 | r | Q | |||||

| ½ | 5.25 | 1.19 | 1.38 | 1.69 | 0.84 | 1.56 | 1.56 | 2.88 | 9.00 | 1.12 | 0.90 | Note-3 | 0.12 | 0.93 | 3.50 | 4 | 0.88 | ||

| ¾ | 5.50 | 1.25 | 1.69 | 2.00 | 1.05 | 1.69 | 1.69 | 3.12 | 9.00 | 1.25 | 1.11 | Note-3 | 0.12 | 1.14 | 3.75 | 4 | 0.88 | ||

| 1 | 6.25 | 1.38 | 2.00 | 2.25 | 1.32 | 1.88 | 1.88 | 3.50 | 9.00 | 1.38 | 1.38 | Note-3 | 0.12 | 1.41 | 4.25 | 4 | 1.00 | ||

| 1¼ | 7.25 | 1.50 | 2.50 | 2.88 | 1.66 | 2.06 | 2.06 | 3.75 | 9.00 | 1.50 | 1.72 | Note-3 | 0.19 | 1.75 | 5.12 | 4 | 1.13 | ||

| 1½ | 8.00 | 1.75 | 2.88 | 3.12 | 1.90 | 2.38 | 2.38 | 4.38 | 9.00 | 1.75 | 1.97 | Note-3 | 0.25 | 1.99 | 5.75 | 4 | 1.25 | ||

| 2 | 9.25 | 2.00 | 3.62 | 3.75 | 2.38 | 2.75 | 2.75 | 5.00 | 9.00 | 2.00 | 2.46 | Note-3 | 0.31 | 2.50 | 6.75 | 8 | 1.13 | ||

| 2½ | 10.50 | 2.25 | 4.12 | 4.50 | 2.88 | 3.12 | 3.12 | 5.62 | 9.00 | 2.25 | 2.97 | Note-3 | 0.31 | 3.00 | 7.75 | 8 | 1.25 | ||

| 3 | 12.00 | 2.62 | 5.00 | 5.25 | 3.50 | - | 3.62 | 6.62 | 9.00 | - | 3.60 | Note-3 | 0.38 | - | 9.00 | 8 | 1.38 | ||

| 4 | 14.00 | 3.00 | 6.19 | 6.50 | 4.50 | - | 4.25 | 7.50 | Note-3 | - | 4.60 | Note-3 | 0.44 | - | 10.75 | 8 | 1.63 | ||

| 5 | 16.50 | 3.62 | 7.31 | 8.00 | 5.56 | - | 5.12 | 9.00 | 12.00 | - | 5.69 | Note-3 | 0.44 | - | 12.75 | 8 | 1.88 | ||

| 6 | 19.00 | 4.25 | 8.50 | 9.25 | 6.63 | - | 6.00 | 10.75 | 12.00 | - | 6.75 | Note-3 | 0.50 | - | 14.50 | 8 | 2.13 | ||

| 8 | 21.75 | 5.00 | 10.63 | 12.00 | 8.63 | - | 7.00 | 12.50 | 12.00 | - | 8.75 | Note-3 | 0.50 | - | 17.25 | 12 | 2.13 | ||

| 10 | 26.50 | 6.50 | 12.75 | 14.75 | 10.75 | - | 9.00 | 16.50 | 12.00 | - | 10.92 | Note-3 | 0.50 | - | 21.25 | 12 | 2.63 | ||

| 12 | 30.00 | 7.25 | 15.00 | 17.38 | 12.75 | - | 10.00 | 18.25 | 12.00 | - | 12.92 | Note-3 | 0.50 | - | 24.38 | 12 | 2.88 | ||

|

Notes: |

|||||||||||||||||||

Choose Robust Special Why Metals for Flanges?

- Large inventory with ready stock

- Wide material selection

- Competitive prices for bulk and small orders

- International quality certifications

- On-time delivery worldwide

We Export Globally

Get high-quality flanges suppliers in Mumbai. With custom solutions available.